Greenhouses with Blu2Light

Blu2Light agricultural project

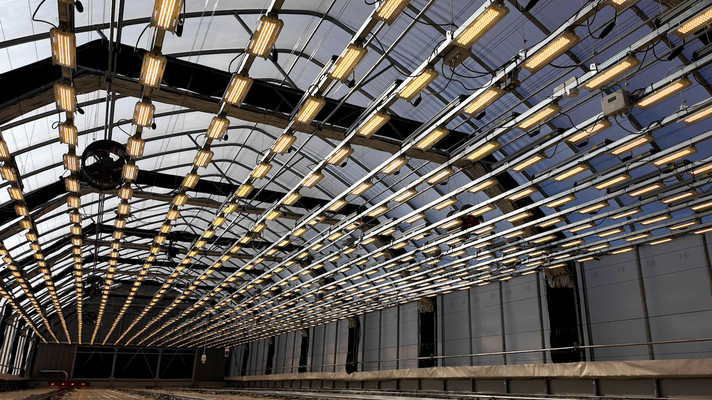

Blu2Light Installation

Revolutionizing Agricultural Production with Advanced Lighting and Environmental Control

The global agricultural industry is witnessing a technological transformation, and AgriSmart, in collaboration with Energywise, RDL Consulting, and Vossloh Schwabe, has implemented a state-of-the-art lighting and environmental control solution for a high-value medicinal plant production facility.

This facility is certified under GACP (Good Agricultural and Collection Practices) for cultivation and holds the prestigious EU-GMP certification for processing and packaging Active Pharmaceutical Ingredients (APIs) to the highest global standards. The integration of precision lighting and environmental monitoring technologies has enabled the facility to achieve superior quality, sustainability, and productivity in a highly regulated industry.

Project Overview

The facility required a specialized lighting system capable of delivering precise light levels to support the growth of high-value medicinal plants. The solution needed to meet strict environmental standards while optimizing energy efficiency and ensuring continuous data monitoring of critical parameters such as temperature, humidity, CO₂, and light intensity.

Three greenhouses were equipped with the Blu2Light lighting control system, forming a unified mesh network. The system communicates with the Blu2Light gateway, which collects and stores data, providing real-time insights through the Grafana platform.

Key Hardware Specifications

The lighting infrastructure is built on the VS Industry 4R technology, utilizing IP65-rated lenses designed for durability and optimal light distribution in controlled environments. This facility employs 30° lenses to deliver focused lighting essential for uniform growth, with flexibility to adapt to future needs through additional lens options of 110°, 90°, and 60°.

Continuous monitoring of temperature, humidity, CO₂, and light levels allows the facility to fine-tune growing conditions for optimal results. This data-driven approach not only enhances yield consistency but also supports compliance with GACP and EU-GMP standards, ensuring superior product quality and traceability.

Seamless Data Integration and Visualization

The Blu2Light system’s integration with the facility’s infrastructure enables seamless communication across all three greenhouses. Data is visualized in real-time via Grafana, offering actionable insights that empower the management team to make informed decisions and implement immediate adjustments for improved outcomes.

This project highlights the transformative potential of integrating advanced lighting and environmental control technology into agricultural operations. Key benefits include:

-Enhanced yield consistency and quality through precise control of light and environmental factors.

-Improved energy efficiency, reducing operational costs while maintaining optimal growth conditions.

-Strengthened compliance with international standards, positioning the facility as a leader in pharmaceutical-grade plant production.

As the global demand for pharmaceutical-grade medicinal plants continues to rise, this project serves as a model for how technology can empower agricultural producers to meet the highest standards of quality, compliance, and profitability.

Used Products:

187212 Blu2Light Industrial Sensor

186768 Blu2Light Connect ME

186667 Extender 64

186954 Blu2Light Air Sensor

187055 BLU2LIGHT LAN GATEWAY